What are the advantages and disadvantages of indirect and direct preheaters?

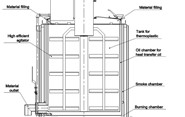

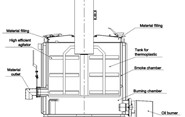

What is the difference between a preheater with direct heating and a preheater with indirect heating?

The thermoplastic material is heated either directly from the burner or via thermal transfer oil in a separate chamber heated by the burner.

Learn more here

Which preheater size should I choose?

A rule of thumb indicates the total preheater volume must be minimum four times the tank capacity of the marking machine;

Learn more here

What is the melting capacity of Borum preheaters?

On average, 2 units of Borum preheaters with indirect heating BM ID-1100 (1100 L each) can melt 10000 kg on a 10-hour working day.

Learn more here

How do I correctly maintain and use my Borum preheater?

The maintenance of the preheaters plays an essential role for both melting capacity and lifetime of the preheaters.

Learn more here

How to properly use preheaters with direct heating?

When starting up don't put too much material in and let it melt while being mixed. Put in a few bags at a time and let them melt before adding more material.

Learn more here

How many chutes do I need for transferring material from my preheater to the machine's material tank?

You can have just 1 chute, which you attach to the preheater that you are taking the melted material from. For your convenience, you can get 1 chute for each preheater you are using, especially if working with different colours.

Learn more here

My burner starts up and then stops right away. What should I do?

It could be that the Cad cell is faulty (no connection or dirty).

Learn more here

Oil spill from ID boilers

it could be because there is water in the heating oil or it could be that there is too much oil in the boiler.

Learn more here

White smoke from the chimney

If there is white smoke coming from the chimney, the burning is not correct.

Learn more here

Is it possible to use a generator as a power source for preheaters instead of the PTO system of a supply truck?

You can get the hydraulic pressure from the PTO and the electric power from the electrical system on the truck (24V).

Learn more here