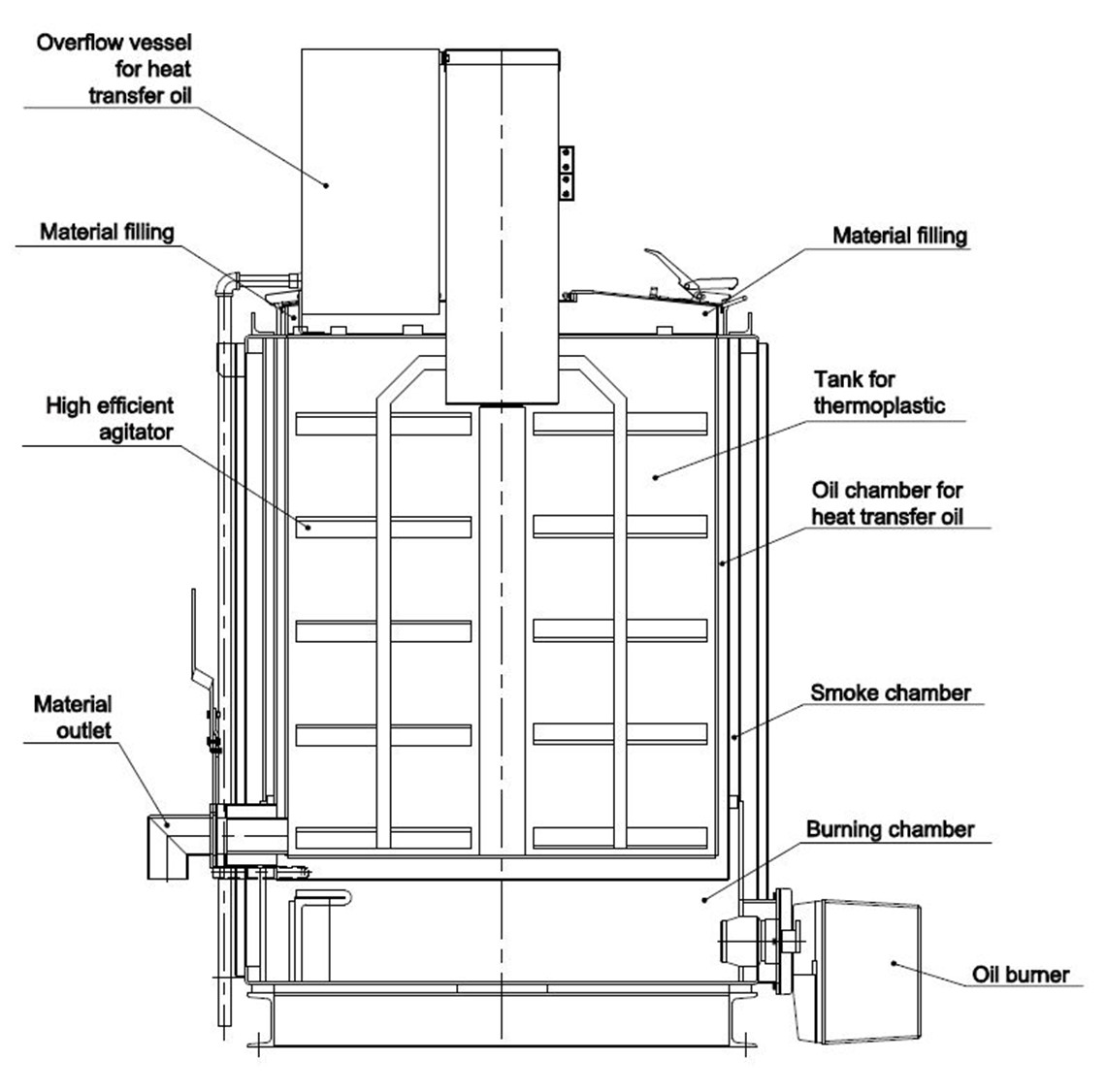

ADVANTAGES OF INDIRECT HEATING

- Better thermal control secures gentle handling of the thermoplastic material. This ensures optimal application conditions in the temperature working area – maximum heating without risk of material damage

- Safe heating conditions via the uniform heat distribution from the thermal oil

- Uniform storage temperature in all parts of the preheater – no hot spots

- Longer lifetime of the preheater due to the more gentle heat supply from the burner – no overheating of the steel parts

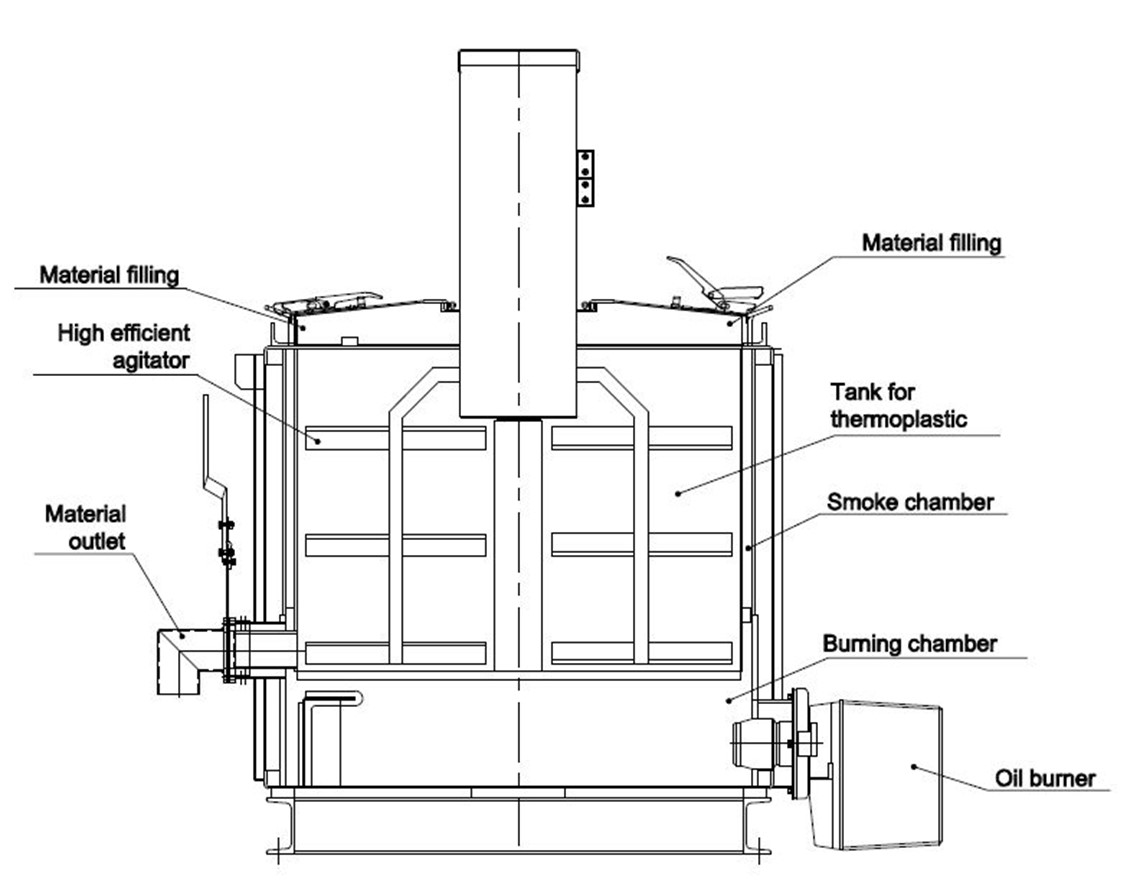

ADVANTAGES OF DIRECT HEATING

- Quick heating time due to the burner only needing to heat the steel of the preheater – no thermal oil as an in-between medium

- Higher melting capacity due to more effect heating in the preheater, which then heats and melts the thermoplastic

- Simple construction – no thermal oil reservoir is build into the construction

- Lower cost price due to the more simple construction

Please address Borum for advice for selecting preheaters.