INCREASE ROAD SAFETY WITH PROFILED MARKINGS

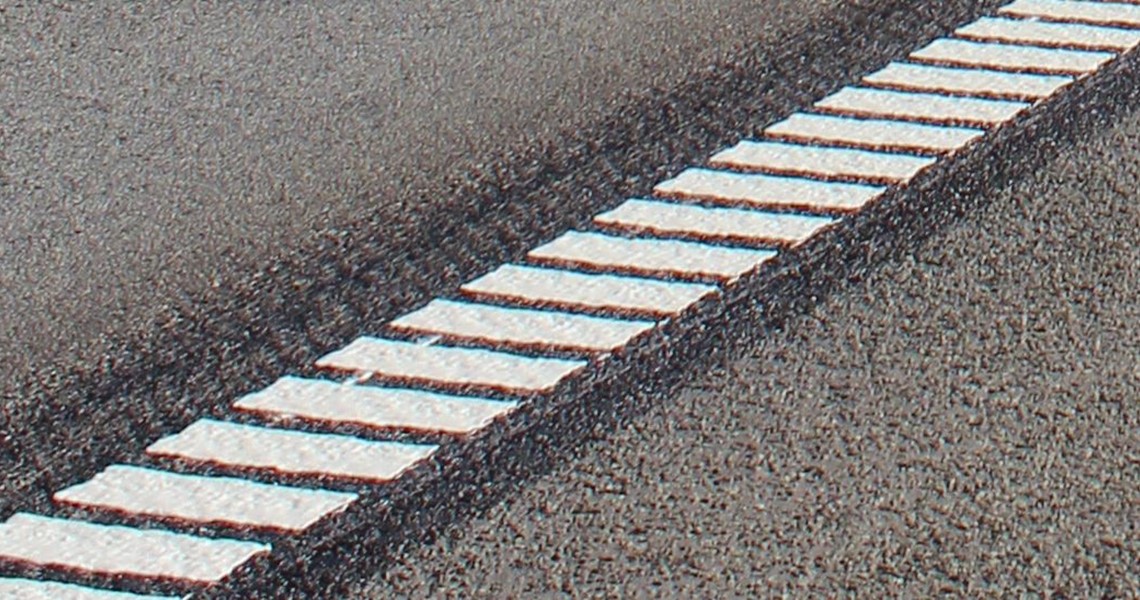

Profiled road markings are the newest road marking technology where a part of the road marking typology is raised over the road surface. This type of markings are becoming more and more popular because of the increased road safety it provides due to high visibility in wet conditions and at night.

HIGH VISIBILITY DURING RAINY WEATHER

The drainage effect of the profiled markings ensures that rainwater will easily drain away from the lines. As a result, the lines are able to maintain high reflective values in rainy weather. This is possible thanks to the structure that allows the water to drain.

HIGH LINE VISIBILITY AT NIGHT TIME

Due to their shape and vertical walls, as well as the possibility of pre-mixing glass beads, profiled lines have a higher retro-reflective level compared to flat lines. This increases the visibility in poorly illuminated areas and during night time.

NOISE ALERT TO AVOID RUN-OFF-ROAD COLLISIONS

Furthermore, the profiled nature of the road marking produces a noise when driven over that will warn the driver against driving off the road. Therefore, profiled markings are often used on roads with high traffic and low night visibility as highways and motorways.

How the Dot'n line extruder works

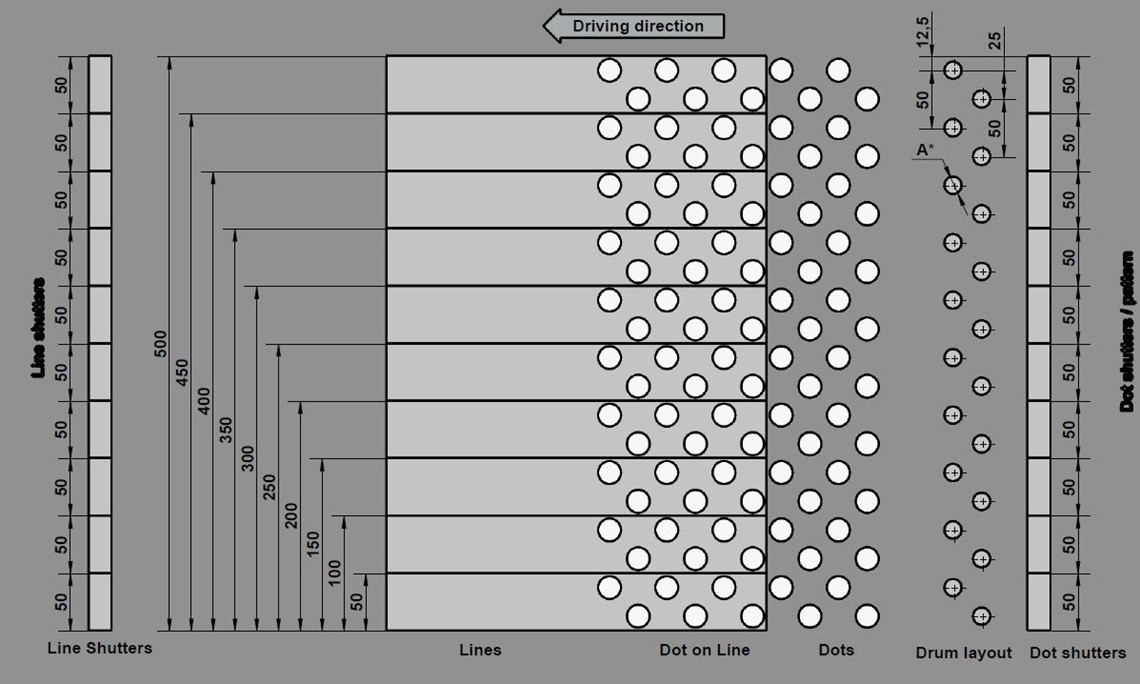

The equipment’s width can be up to 50 cm/20” (maximum width depends on the machine model). The line width starts at 5 cm (2”) and can be built up with 5 cm (2") standard shutters.

- The line thickness is usually between 3 - 5 mm (118 mils - 197 mils).

- The application speed depends on the type of application and goes up to 6 km/h (3.8 mph).

- Available in 30, 40, 45 and 50 cm (12”, 16”, 18”, 20”) widths as standard.

The equipment is supplied with two sets of shutters - one set for applying flat lines and profiled markings and one set of shutters for applying dots. This set-up makes it possible for the equipment to apply various line types and patterns as well as a combination of dots over line. By using two sets of shutters the base line has time to cure slightly before the dots are applied and consequently, the dots will settle on top of the line with sharp edges, securing the optimum retroreflection.

.

LINES TYPES THAT CAN BE APPLIED WITH THE DOT'N LINE EXTRUDER

SCREW PUMP WITH CONTINUOUS RECIRCULATION SYSTEM

The transport of material from the machine's material tank to the Dot’n’Line head is done by a hydraulically driven screw pump, which is electronically controlled. The screw pump has a permanent thermoplastic recirculation system (that includes inactive extrusion valves), which ensures a constant material flow and keeps solid parts from adhering and ready for opening.

AUTOMATIC CLEANING FUNCTION

The cleaning function is triggered by the push of a button from the machine's LineMaster computer and can be activated while driving. This will open all active shutters and push the extra material out.

WHY CHOOSE THE DOT’N LINE thermoplastic extrusion EQUIPMENT?

3-1 SOLUTION that allows you to make flat lines, dots and a combination of dots over the line using only one equipment.

EFFECTIVE HOT-OIL HEATING OF ALL SIGNIFICANT PARTS OF THE EXTRUDER ensures that the thermoplastic material does not stiffen and set inside the equipment. Borum uses a centrifugal pump, which opposite to often used gear pumps, increases the flow of oil when the heat transmission oil heats up.

A CONTINUOUS CIRCULATION OF THE THERMOPLASTIC MATERIAL INSIDE THE EQUIPMENT ensures its homogeneous viscosity. The circulation avoids settling and catching of the heavy/solid pars and prevents unnecessary wear of the mechanical parts.

BUILD-IN PRESSURE REGULATING SYSTEM ensures that line width and thickness does not change no matter the number of shutters involved in the current marking assignment.

ADVANTAGES OF THE DOT'N LINE EQUIPMENT AND PROFILED MARKINGS

- Less material consumption for dotted lines compared to flat lines.

- Relatively fast application speed.

- Having numerous dots gives the light a lot of possible areas to fall onto and create a retro-reflective effect. that makes the marking visible during both day and night time.

- Rain will easily drain away from the line, so road lines will remain highly visible during wet weather.

- Having clear visibility, especially while driving during night time.

- Noise will alert drivers when driving on the line and will prevent him from driving off-road.

THERMOPLASTIC DOT SPECIFICATIONS

The number of dots per meter line can be set from 15 – 35. The dots' diameter can be chosen between ø20 and ø45 mm (ø0.8” and ø1.8”). The dot size is a result of the diameter of the holes found in the equipment's rotating drum and the pump pressure.

The number of Dots across the line is determined by the size of the shutters:

- For 50 mm (2”) shutters there will be 25 mm (1”) space between the centers of the dots.

- For 60 mm (2.4”) shutters there will be 30 mm (1.2”) space between the centers of the dots.

- For shutters with a width of 70, 80 and 90 mm (2.8”, 3.1” and 3.5”) the distance between the holes will be determined together with the customer.

The number of Dots across the line is determined by the size of the shutters:

- Holes ø12 mm (0.5”) in the drum give DOT diameter of 18 to 25 mm (0.7” to 1”). Ø12 mm (0.5”) holes are chosen when marking with Dots on base line shall be made.

- Holes ø15 mm (0.6”) in the drum give DOT diameter of 25 to 30 mm (1” to 1.2”).

- Holes ø18 mm (0.7”) in the drum give DOT diameter of 30 to 35 mm (1.2” to 1.4”).

- Holes ø22 mm (0.9”) in the drum give DOT diameter of 35 to 45 mm (1.4” to 1.8”).

EXAMPLES OF DOT MARKINGS IN DIFFERENT SIZES

EXAMPLE OF POSSIBLE LINE WIDTHS AND DOT SIZES WITH A STANDARD 50 CM DOT'N LINE EXTRUDER

AUTOMATIC CONTROL OF MARKING EQUIPMENT WITH THE LINEMASTER COMPUTER

The LineMaster computer offers you full control over your Dot'n line thermoplastic extruder. This makes it easy to control the application and make adjustments on the go without compromising on the quality of the markings.

How does the LineMaster computer support line marking with the Dot'n line extruder?

There is no need for a start-up distance - the LineMaster simply leaves the equipment in idle mode.The Dot’n Line equipment is able to start up after several hours of pausing in idle mode and still deliver the exact same quality from the first millimeter.

The Dot’n line performance is 100% automatically adaptable to changes in speed. Within a specific speed range, the BM LineMaster automatically increases or decreases an internal circulation rate according to the speed of the machine and thus compensate for the difference in thermoplastic consumption at different speeds.

The feeding pump for the thermoplastic is also controlled by the LineMaster and can be adjusted while performing marking work. Furthermore, each shutter can be individually controlled from the LineMaster. So you can digitally control the shutters, without any mechanical interference.