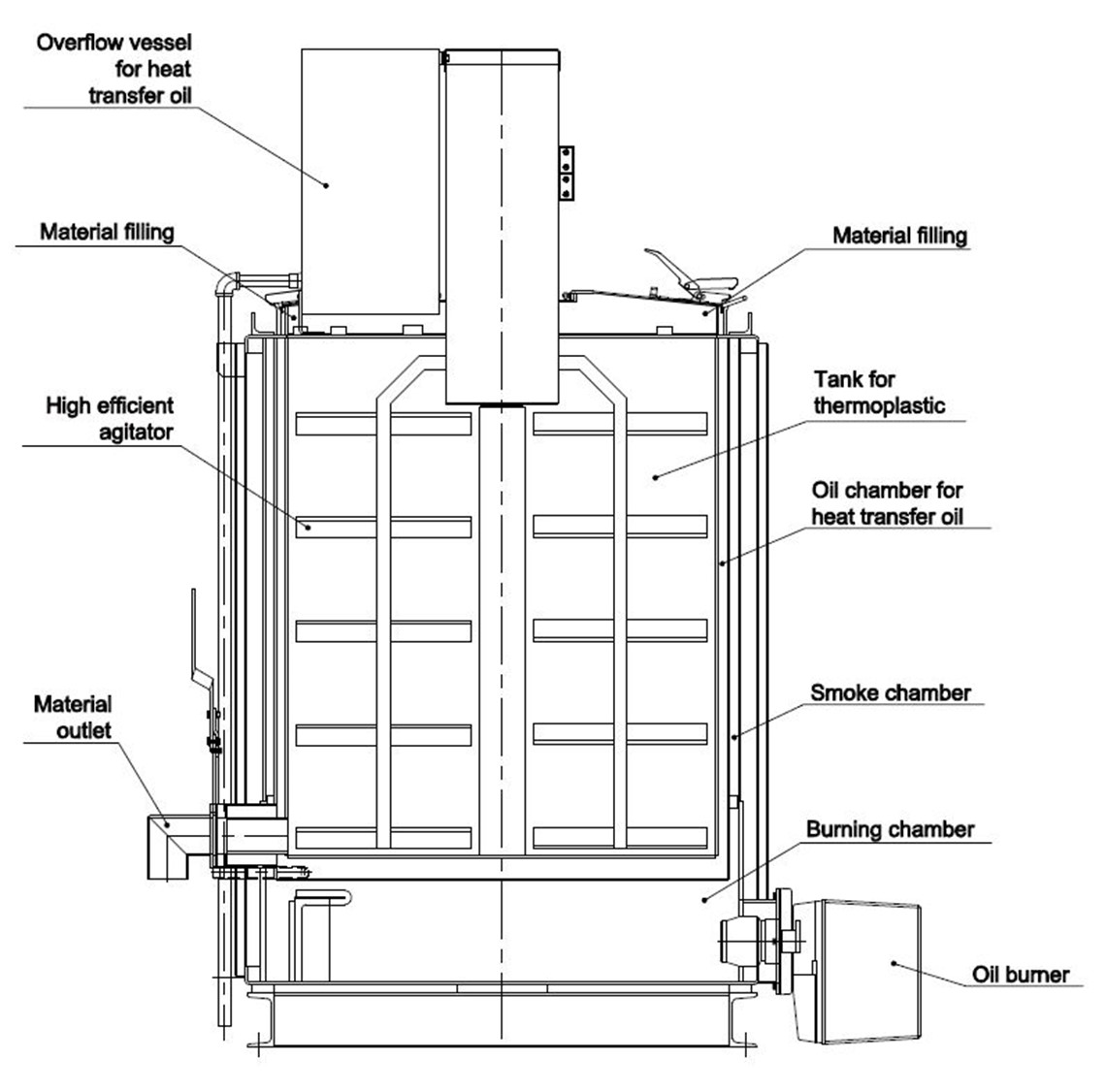

INDIRECT HEATING VIA THERMAL OIL

The thermoplastic material is heated via thermal transfer oil in a separate chamber heated by the burner. The oil chamber is found in the preheater's side walls. Therefore, the heating of the thermoplastic material is done from various angles due to the oil chambers surrounding the preheater. This is different compared to the direct heating system where the heating is done from one location - the bottom of the preheater.

ADVANTAGES OF INDIRECT HEATING

- Better thermal control secures gentle handling of the thermoplastic material. This ensures optimal application conditions in the temperature working area – maximum heating without risk of material damage

- Safe heating conditions via the uniform heat distribution from the thermal oil

- Uniform storage temperature in all parts of the preheater – no hot spots

- Longer lifetime of the preheater due to the more gentle heat supply from the burner – no overheating of the steel parts

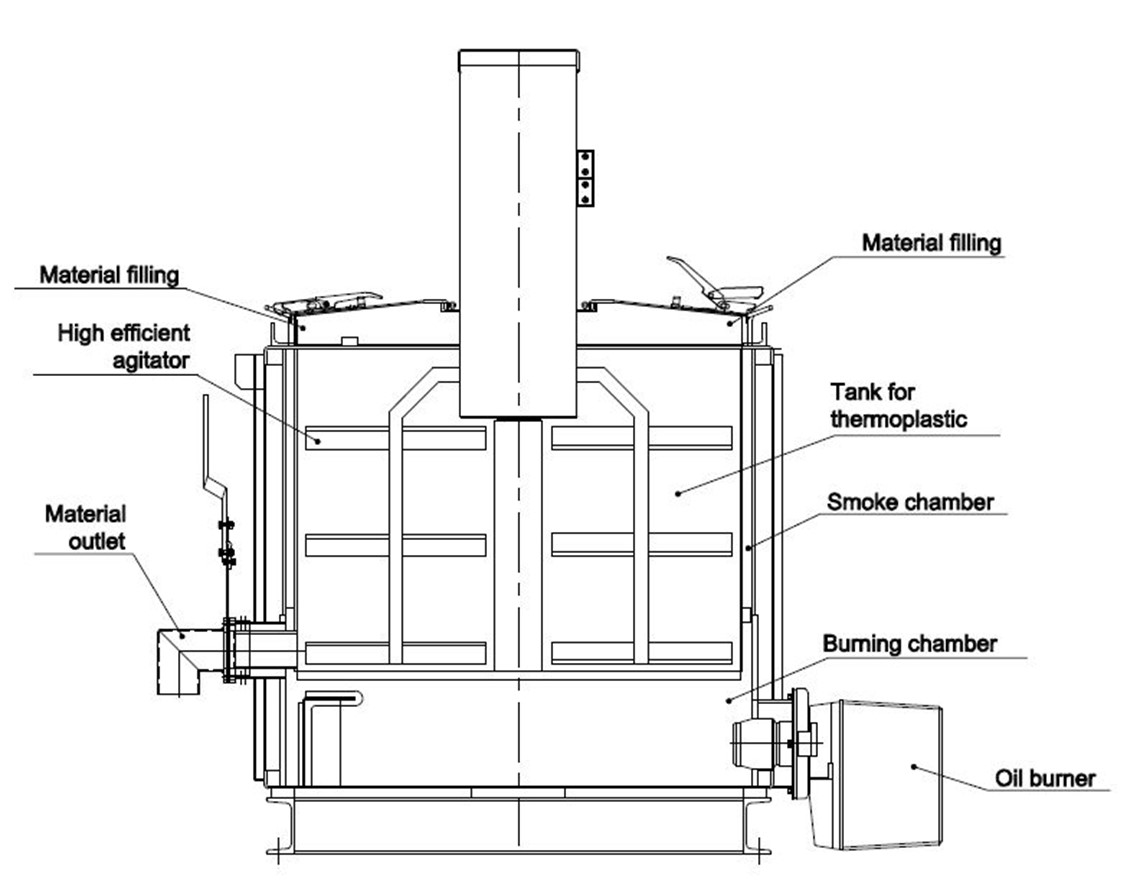

DIRECT HEATING VIA BURNER

The thermoplastic material is heated directly from the burner, which is placed at the bottom of the preheater. Therefore, the heating of the thermoplastic material is done from this one location - the bottom of the preheater. This is different compared to the indirect system where the heating of the thermoplastic material is done from various angles due to the thermal transfer oil found in the oil chambers surrounding the preheater.

ADVANTAGES OF DIRECT HEATING

- Quick heating time due to the burner only needing to heat the steel of the preheater – no thermal oil as an in-between medium

- Higher melting capacity due to more effect heating in the preheater, which then heats and melts the thermoplastic

- Simple construction – no thermal oil reservoir is build into the construction

- Lower cost price due to the more simple construction

The burner is powered either by diesel oil or propane gas. However, the version we can see is most popular on the market is with diesel burners. Diesel has the advantage that it is not considered as dangerous goods when transported on a truck. Furthermore, it is easier to handle and refill diesel in a fuel tank than exchanging the propane tanks for the gas burner.

The preheaters are also supplied with a thermostat for thermoplastic material temperatures from +50 °C (122 °F) to 270 °C (+482 °F). This includes an integrated display showing actual thermoplastic temperature.