Photo © Geveko Markings Denmark

Spray applications are used for applying flat lines, also known as non-profiled or type 1 markings. Flat lines are mainly used in well-illuminated areas as urban roads for e.g. where the lines do not need high retroreflectivity levels.

No matter what material you use (cold paint, 2 component cold plastic or thermoplastic spray), with one gun you can obtain a high-quality line up to 20 cm in width depending on work conditions, application speed, layer thickness, wind, etc. You can increase up to 3 guns if choosing the standard Borum retainer or up to 5 guns if you opt for the wide Borum retainer.

Pressurized cold paint spray

Atomizing air

Line types: Flat lines (continuous and interrupted lines)

Equipment: BM C 6 gun with 6 mm nozzle as standard or you can optionally choose a Kamber gun that comes with a variety of nozzle sizes

*Borum machines can also be supplied with a combination of cold paint and thermoplastic equipment.

Air spray with atomizing air is a method of marking that uses compressed air to spray the paint onto the road surface. The finely atomized paint produces a thin and smooth layer, but the rebounding air flow causes paint scattering, which can be noticeable around the edges of the line. The paint can be mixed with glass beads.

The pressure is established by using a pressure tank for the material. The thickness of the line is controlled by the nozzle size and material pressure in the gun, and regulated relative to the speed (i.e. if you drive faster the thickness of the line will decrease unless you put more pressure on the material tank).

The width of the line is controlled by the height of the spray-gun above the ground, and the spray angle of the nozzle. For wide lines usually two or more guns are used.

- The BM C 6 can work with a paint marking pressure up to approx. 8 bar

- An air capacity of 300-700 L/min. is needed per gun

- You can have up to 3 guns if choosing the standard Borum retainer or up to 5 guns if you opt for the wide Borum retainer (NB! Ensure sufficient compressor capacity according to the number of guns).

- With the Borum BM C6 paint gun that has a nozzle of 6 mm you can apply line widths ranging from 8 to 20 cm depending on work conditions, application speed, and layer thickness.

- Line thickness is typically between 0.25 mm to 0.80 mm

- Working speed can be up to 15 km/h depending on the conditions, e.g. material, line type and operator experience

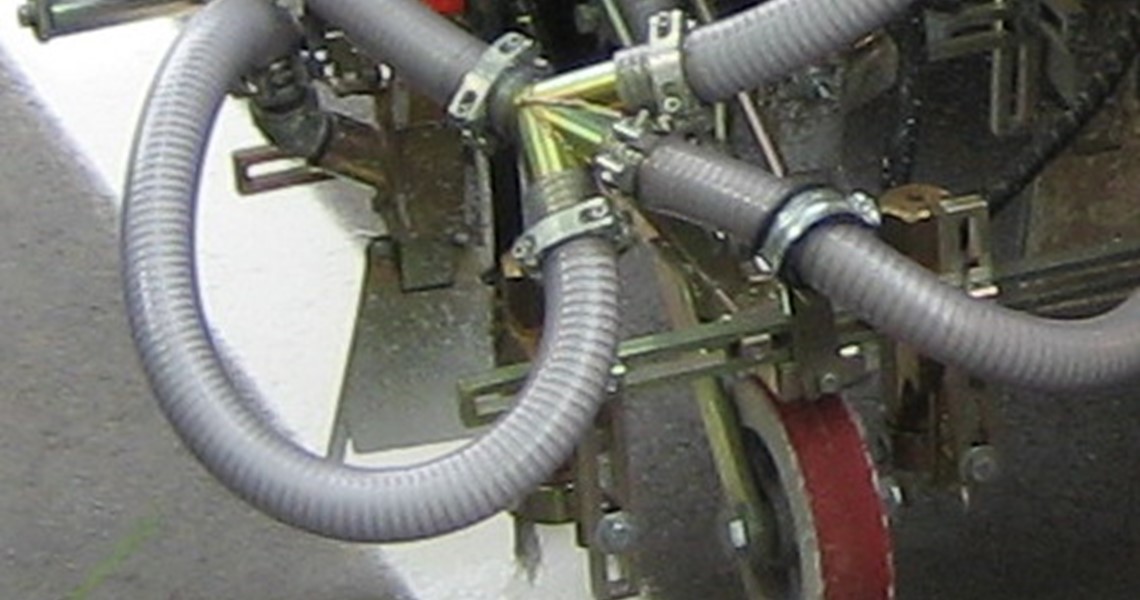

- For all Borum spray machines, the equipment is mounted on a sliding retainer frame as standard that allows you to quickly slide the equipment from one side to another

- Can be equipped with multiple material tanks so that multi-colour marking can be carried out simultaneously (rule of thumb: one compressor can handle up to 2 guns; 2 compressors 3 guns and upwards).

Cold paint airless spray

Line types: Flat lines (continuous and interrupted lines)

Equipment: Wagner GA400-A guns, large selection of nozzles

*Borum machines can also be supplied with a combination of cold paint and thermoplastic equipment.

High-pressure airless spraying uses a high-pressure airless piston pump to spray the paint. The airless spray paint is sharper and smoother than atomized spray as there is no high-speed airflow to scatter any rebounding paint.

The marked lines are neat and more clear-cut compared to atomizing spray paint. This method can apply paints of high viscosity, and apply relatively thick layers in a single pass. However, the paint cannot be mixed in with glass beads as in the case of atomizing spray equipment due to the pump.

- Can be equipped with multiple material tanks with separate airless pumps, so that multi-color marking can be carried out simultaneously.

- High-pressure airless pump with a volume of 23 L/min.

- Maximum pressure is 270 bar

- We offer a large selection of nozzle sizes for this type of application. The choice of nozzle is made based capacity of the pump, number of guns, application speed, material type, layer thickness and line type,

- Possibility to apply line widths up to 25 cm with standard nozzles depending on line thickness, work conditions, and application speed. You can also choose from a wide range of nozzle sizes depending on your requirements.

- You can have up to 3 guns if choosing the standard Borum retainer or up to 5 guns if you opt for the wide Borum retainer.

- Working speed can be up to 15 km/h depending on the conditions, e.g. material, line type and operator experience

- For all Borum spray machines, the equipment is mounted on a sliding retainer frame as standard that allows you to quickly slide the equipment from one side to another

2 - component cold plastic spray (98:2)

Atomizing air

Line types: Flat lines (continuous and interrupted lines)

Equipment: Kamber gun

- Low-pressure system using paint guns with atomizing air

- Maximum paint pressure is up to 10 bar

- The LineMaster computer can activate an alarm when hardener does not flow during marking work

- The LineMaster computer can activate an alarm when there is a break in the marking works (which is longer than set in the computer)

- Possibility to apply line widths of up to 20 cm with one gun depending on work conditions, application speed, and layer thickness. The machine can be supplied with one or two spray guns.

- Working speed can be up to 10 km/h depending on the conditions, e.g. material, line type, and operator experience

- The cleaning process is an automated preset sequence ensuring the correct valves are opening/closing. The system is activated via the Borum LineMaster computer.

- For all Borum spray machines, the equipment is mounted on a sliding retainer frame as standard that allows you to quickly slide the equipment from one side to another

- The sliding retainer frame can be used for all Borum 2-component equipment, which makes switching equipment easy and quick.

- Optional: Depending on the configuration, the system can handle working with both 2-component cold plastic and cold paint

2 - component cold plastic spray (98:2)

Airless spray

Line types: Flat lines (continuous and interrupted lines)

Equipment: Kamber guns, large selection of nozzles

- Double-action piston pump with two pistons for the paint and one piston for the hardener. The 3 pistons are driven by a common hydraulic motor in order to secure the right relation between paint and hardener. A static mixer is mounted close to the paint guns.

- Efficient pump with less wear and tear than other product available on the market. The pump has a sensor for registration of the paint flow. The pump capacity is up to 45 L/min (12 gal/ min).

- The LineMaster computer can activate an alarm when hardener does not flow during marking work

- The LineMaster computer can activate an alarm when there is a break in the marking works (which is longer than set in the computer)

- Pulsation damper in the hydraulic oil circuit, which helps minimize piston pulsations

- High-pressure paint filter

- Possibility to apply line widths of 25 cm with standard nozzle depending on the nozzle choice, line thickness, work conditions, application speed and layer thickness.

- Working speed can be up to 15 km/h depending on the conditions, e.g. material, line type and operator experience

- The cleaning process is an automated preset sequence ensuring the correct valves are opening/closing. The system is activated via the Borum LineMaster computer.

- For all Borum spray machines, the equipment is mounted on a sliding retainer frame as standard that allows you to quickly slide the equipment from one side to another

- The sliding retainer frame can be used for all Borum 2-component equipment, which makes switching equipment easy and quick.

- Optional: Depending on the configuration, the system can handle working with both 2-component cold plastic and cold paint

Thermoplastic spray via pressurized tank

Line types: Flat lines (continuous and interrupted lines)

Equipment: BM SP 3000 Spray plastic gun

(Optional narrow nozzle size of 3 mm or wide nozzle size of 7 mm)

The amount of product that is put on the road is regulated by the pressure of the tank and the pressure of the sprayed air. In other words, the application pressure is kept at the same level as in the pressure tank. This offers you an easy to use the system.

After starting the application, the thickness of the line is only affected by the machine speed. Therefore, it is necessary to keep a constant speed in order to maintain a uniform and consistent line thickness. This is useful for applying thicker lines in curves and areas with higher wear and tear levels.

The maintenance for the pressure tank is minimal if compared to the thermoplastic spray pump system. Furthermore, due to not having a pump, the system has less mechanical parts that can be worn out at the time.

- Material pressure is created by the compressor

- The pressure tank can handle 8.5 bar, but usually, a pressure of 1-5 bar is used

- The atomizing air pressure is adjusted with the material pressure and depends on the material pressure and the viscosity of the material. We recommend that the atomizing air pressure to always be min. 1 bar higher than material pressure.

- A minimum air capacity of 600 L/min. is needed per gun

- Possibility to apply line widths ranging from 10 - 20 cm with one spray gun depending on line thickness, work conditions, application speed and layer thickness.

As an alternative, we offer a narrow nozzle, which can spray 5-15 cm with one gun. - Line thickness is typically between 0.75 mm to 1.5 mm

- Working speed can be up to 15 km/h depending on the conditions, e.g. material, line type and operator experience

- The thermoplastic spray equipment is mounted on a slidable retainer. This will allow for work to be done on both left and right sides. This also makes it very easy to slide the equipment from one side to the other in only a few minutes and with minimal mechanical interference.

Thermoplastic spray via pump

Line types: Flat lines (continuous and interrupted lines)

Equipment: BM SP 3000 Spray plastic gun

(Optional narrow nozzle size of 3 mm or wide nozzle size of 7 mm)

The amount of product that is put on the road is regulated by the pressure of the pump and the pressure of the sprayed air. After starting the application, it is possible to set the amount of material in relation to the machine speed.

There are three major advantages when using a spray pump system:

- Increased safety as there is no risk of backsplash of hot material due to pressure in the tank.

- The ability to quickly adjust the pressure while driving. To some extent, this can be done automatically from the Borum LineMaster computer that Borum machines are equipped with.

- The filling and filtration of thermoplastic are easier due to the lid of the non-pressurized tank being larger compared to the pressurized one.

- When using a pump-based system, the tank is non-pressurized

- The amount of the applied material is set by the pressure of the pump and the air pressure of spraying. It can also be set to automatically adjust to the speed of the machine through the LineMaster Computer.

- The system is designed for pressure up to 8.5 bar, but in practice, it will typically be about 1-5 bar

- Pump volume is up to 80 L/min

- A minimum air capacity of 600 L/min. is needed per gun

- Possibility to apply line widths ranging 10 - 20 cm with one spray gun depending on line thickness, work conditions, application speed and layer thickness. As an alternative, we offer a narrow nozzle, which can spray 5-15 cm with one gun.

- Line thickness is typically between 0.75 mm to 1.5 mm

- Working speed can be up to 15 km/h depending on the conditions, e.g. material, line type and operator experience

- The thermoplastic spray equipment is mounted on a slidable retainer. This will allow for work to be done on both left and right sides. This also makes it very easy to slide the equipment from one side to the other in only a few minutes and with minimal mechanical interference.