The challenge of keeping the lines intact

In recent years, there has been a great effort to find out which road marking methods best meet the challenges of keeping the lines intact throughout the year - even in the cold winters.

The goal is to maintain the properties of road markings over time, so that the need for repairs and new markings doesn't occur too soon. Wear can be registered both as physical reduction in area and thickness, but also as reduced functional ability. Wear from studded tires and mechanical stresses from winter operations, such as snow plows, are a major challenge in this context. Wear over time is affected by external factors that can be divided into "mechanical" as well as "chemical" factors.

Consideration must be given to which methods are best suited to meet the functional requirements in a life expectancy analysis. The decision is subject to a cost/benefit assessment, and must of course be within the opportunities provided in the budgets. Important parameters to consider in this cost/benefit analysis are; the road marking material, the line types and the maintenance strategy.

Typical mechanical wear:

- Traffic load, driving on the lines.

- Winter operations, such as snow plows

- Studded tire use in the winter

The macrotexture of the asphalt surface, i.e. the roughness of the surface, will also affect the mechanical wear.

Typical "chemical" wear factors:

- Salting on winter roads

- Other pollution (oil spill, etc)

- The sun's UV radiation

Which types of markings can survive the snow plow (to a certain degree)?

To spare the lines from mechanical stress, the best option would of course be to place the road markings in a milled track. This way the road markings are physically protected from the blade of the snow plow. However, this solution is not always accepted, since the milling cuts open the asphalt, and as a consequence, the lifetime of the road risks being affected.

Alternatively, if it's not an option to place the road markings in a milled track, then you can place a "sacrifice" line/guideline next to the profiled markings, to protect the profiles from the blade of the snow plow.

As a third option, you can choose a type of marking such as the Stair-flex line or the Edge-flex line (comb line), where the blade from the snow plow will slide on the line and not "grip" the edge of the markings so easily. This solution works best when the snow plow blades in rubber are used because snow plow blades in a harder material have a higher risk of damaging the whole line.

To sum up the options for types of markings that can survive the snow plow:

- Markings in a flat milled track

- Stair-Flex markings or similar

- Profiled markings with a protective continous line / "sacrifice" guideline

Material characteristics for cold regions

Another important factor in meeting the challenges for line markings in cold regions is to choose the right marking material! It's important that the materials used for the road markings have a certain cold flexibility; The road marking material should be flexible at low temperatures, so it is not excessively crushed during studded tire exposure and snow plow contact. However, it should also have sufficient hardness on hot summer days to avoid rolling out and being deformed / having tire imprint.

We recommend that you ask your material manufacturer for additional info.

Test of various snow plows comparing the damage on the road markings

In 2018 a snow plow test on 8 different types of road markings was carried out by a Danish road marking development group with the participation of the Danish Road Directorate. The test demonstrated the effect of 3 types of snow plow blades on the different types of road markings.

The purpose of the test was to determine RL values as a measure of wear and degradation of the road markings.

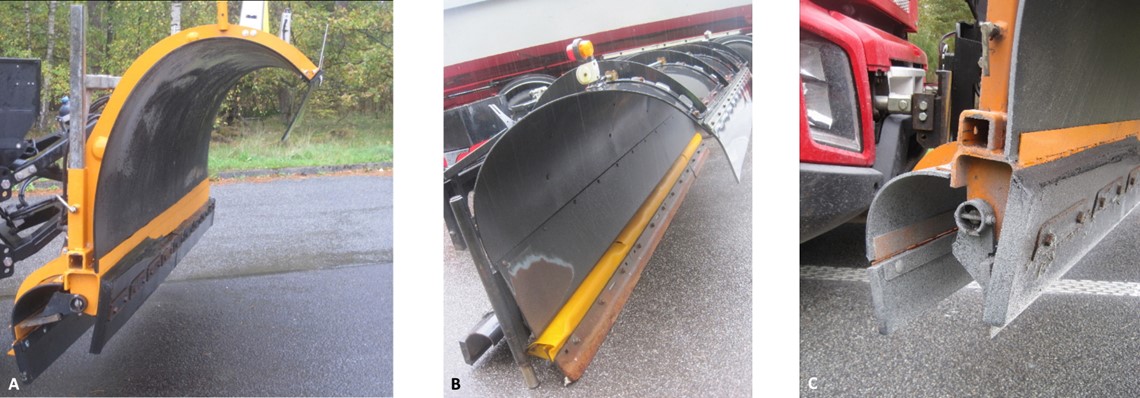

For this testing, three different plows were used: A - Rubber blade; B - Steel/ceramic blade; C - Hard metal blade.

Three different snow plows (from the left): A - Rubber blade; B - Steel/ceramic blade; C - Hard metal blade.

Results of the test

It was agreed to carry out 10 runs with each of the 3 plows in the order A, B and C plows, corresponding to an increasing degree of wear on the road markings, and with a speed of 50 km/h. In addition, it was agreed that RL values are measured initially and repeated after use of each of the three plows.

After the test, there was general agreement that the wear caused by plow A was weak. The wear from plow B was judged to be stronger, and plow C was clearly the strongest - there was a visible beam of abraded material from the plow during the runs, resulting in abraded material deposited around the road markings.

Final state of the road markings

The image on the side shows the surfaces of the road markings in the final states after the use of all three plows, A, B and C.

The image shows that the road markings are more affected by the plows on one side than on the other. This is due to a rather large lateral curve of the road, that makes the plows act stronger on the sides towards the middle of the road.

The RL values of the road markings were measured before as well as after the test, and showed a decrease corresponding to an average of 23 %. This decrease can be attributed to the overall effect of the plows, of which plow C can probably be attributed most of the decrease.

Find more relevant information about road marking on Borum knowledge lab!

References: Norwegian Public Roads Administration (2019) Report title: "Lærebok vegoppmerking".

Sørensen K., Johnsen C. (2019) Report title: "Low noise profiled road markings - reflection properties, noise and test with snow plow".