Airport line marking is challenging due to very distinctive maintenance and safety requirements. As traffic is constantly increasing, this also adds time-pressure to all airport-related functions. Operators and equipment are expected to perform as quickly as possible within a demanding setting. Efficient solutions are required due to the small window of time presented in such a busy environment.

Borum provides self-propelled airport line marking solutions and offers a wide range of specific airport line marking machines that can be tailored to the requirements and needs of the airport.

How do pressurized and airless spray applications differ?

What to keep in mind when choosing an airport marking machine

What is characteristic of most airports is the need to mark large areas, which means that the capacity and efficiency of your machine are key factors.

In most airports, the marking of runways is done by cold paint or cold paint airless application without the use of beads. When choosing your airport line marking machine you should take the below-mentioned needs into consideration. If you outline the requirements then we will help you find the machine which is most suitable for the job:

- The need for different markings types throughout the airport

- The need for different colors of the markings

- The need for different sizes of the lines and extra wide lines,

depending on their function

Extra wide lines and multi-colour marking - common marking requirements in most airports

In accordance with the line width you require, a wide retainer and up to 5 paint spray guns and 5 glass bean guns can be mounted. This assures that the application is performed in a single pass and can be up to 125 cm (approx. 49 inches) depending on line thickness, work conditions, and application speed.

All cold paint Borum machines are equipped with a sliding retainer frame as standard that makes handling the application equipment easier and quicker.

Furthermore, Borum cold paint application machines can be equipped with more material tanks (and separate airless pumps), so that multi-color marking can be carried out simultaneously.

EXTRA WIDE LINES BEING APPLIED ON RUNWAY IN AUSTRIA

YELLOW AND BLACK MARKING APPLIED IN QUEEN ALIA AIRPORT IN JORDAN

Self-propelled line marking machines vs. hand-pushed machines

Although hand-pushed machines are convenient for small-scale projects, they are not efficient for airports. To illustrate the advantages of a self-propelled machine, we have compared the performance of Borum’s smallest model, the BM 2000 to a hand-guided machine on a 9.540m (5.9 miles) stretch.

BM 2000:

- Can cover up to 795m (869 yards) at a time, taking six minutes – Total 72min

- Has to refill tank 11 times, taking 15min – Total 163min

- Overall total time – 237min

Hand-pushed machine:

- Can cover up to 195m (213 yards) at a time, taking 7.8min – Total 382min

- Has to refill tank 48 times, taking 11min – Total 528min

- Overall total time – 920min

Overall, hand-pushed machines take almost four times longer than a Borum City machine to finish the same project. Under tight deadlines, contractors may be under pressure to complete jobs in a timely manner, with a line precision that hand-pushed machines cannot achieve. Self-propelled line marking machines are the better choice for busy airport environments.

Efficient high-capacity airport marking machines

We have designed three category solutions with airport line marking in mind that can accommodate the requirements and application needs you may have

BM 2000 - A small and flexible self-propelled line marking machine

The BM 2000 is a small and highly agile self-propelled line marking machine, perfectly suited for airport marking as well as road marking in the urban environment.

The BM 2000 can be equipped for airless cold paint application, which is the usual application method required in airport marking due to the sharp lines it can apply. However, we can also equip it for pressurized cold paint application if you prefer.

The machine can be equipped with two material tanks of 220 L, which offer the possibility of marking in two colors when working with pressurized cold paint application (one color for airless cold paint application) or one large material tank of 440 L for one color.

NB! The BM 2000 can only work with one colour for airless cold paint marking.

BM 3000 - HIGHER CAPACITY FOR LONGER TARMAC AREAS

Its increased material capacity and compromise between size and maneuverability make the BM 3000 very suitable for marking larger areas with fewer refilling stops.

The BM 3000 can be equipped for airless cold paint application, which is the usual application method required in airport marking due to the sharp lines it can apply. However, we can also equip it for pressurized cold paint application if you prefer.

The machine can be equipped with two material tanks of 440 L (and two separate airless pumps), which offer the possibility of marking in two colors or one material tank of 440 L for one color.

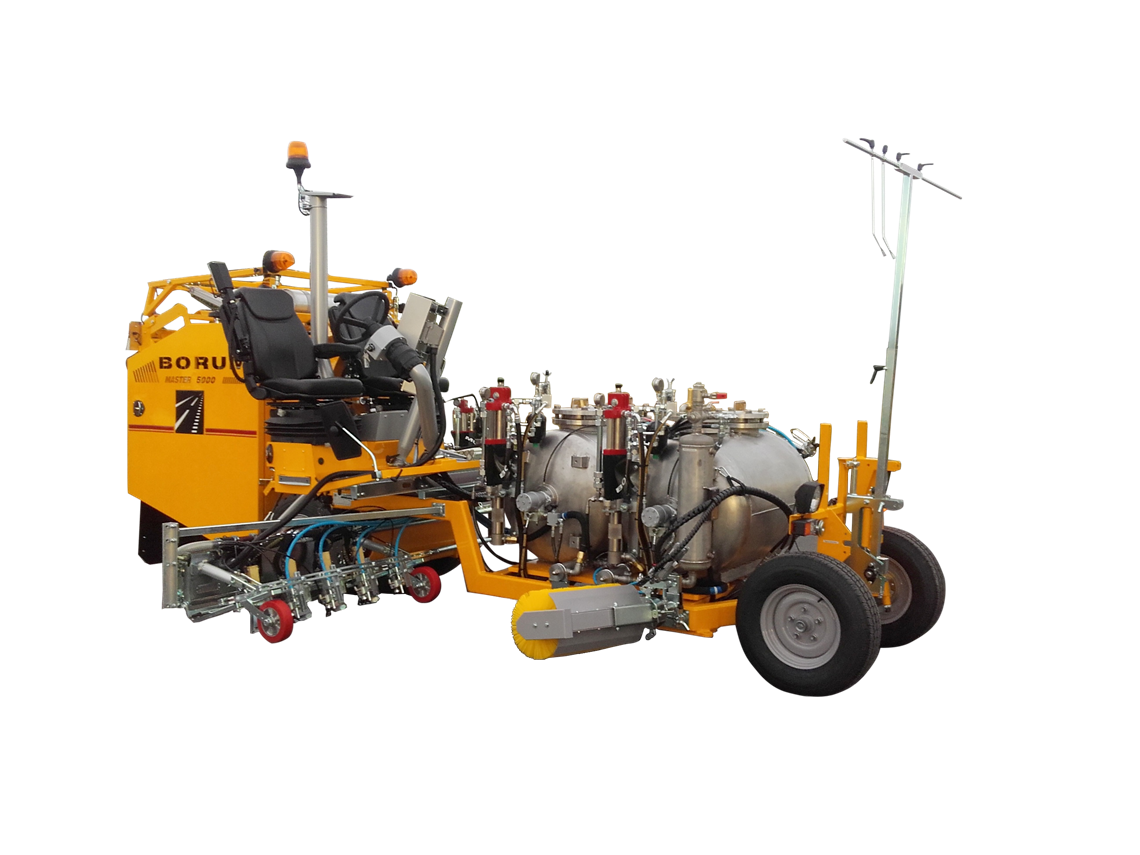

BM 5000 - MAXIMUM CAPACITY AND POWER FOR MAJOR MARKING PROJECTS

The BM BM 5000 is our largest self-propelled line marking machine. Its high capacity and power make the BM 5000 the best and most uncompromising choice for any major line marking job.

The BM 5000 can be equipped for airless cold paint application, which is the usual application method required in airport marking due to the sharp lines it can apply. However, we can also equip it for pressurized cold paint application if you prefer.

The machine can be equipped with two material tanks of 440 L (and two separate airless pumps), which offer the possibility of marking in two colors or one material tank of 440 L or 1000 L for one color.